Sept 30, 2020

We got first light on Gemini! Undulator gap has been closed to 7 mm so far, and all the vacuum is holding up. Commissioning will continue with a complete radiation check at each step when closing the gap. After that, we will calibrate the monochromator, and work on optimizing the flux, which may entail realigning some of the optical components on the floor with the help of the Survey and Alignment group. After that, the alignment of the endstation begins. The overall goal is to get the first diffraction dataset by the end of the year before the ALS goes down for its 3-month shutdown.

March 29, 2020

Berkeley Lab shut down the day before we were to start commissioning Gemini. We understand the need for shelter-in-place due to COVID-19, but are hugely disappointed by the timing. Hope everyone stays safe and healthy in these uncertain times. More to come when we are up and running again and can reschedule the commissioning shift.

Feb 12, 2020

The Gemini BRR (Beamline Readiness Review) was held today and it went well. This is the final review of a beamline before it is allowed to take light. There was one outstanding item, which was that the EPS system testing is not yet considered final. The EPS group is working hard on this final item, and hope to have it completed within a few weeks.

Jan 31, 2020

We have been testing the Gemini robot with LN in the dewar to see how many continuous mounts can be made without a warmup of the gripper. Twenty pucks and counting as of this video.

Dec 23, 2019

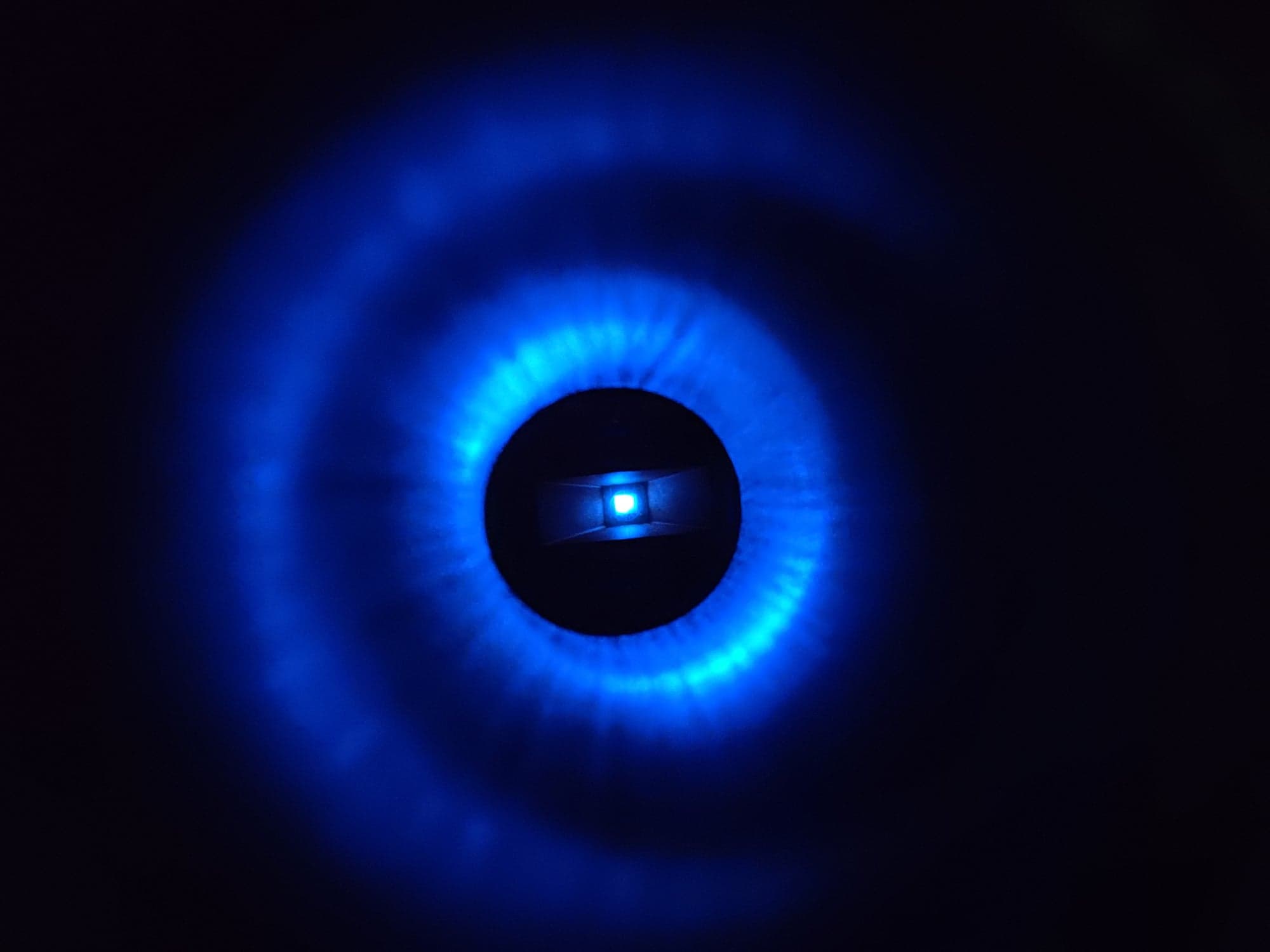

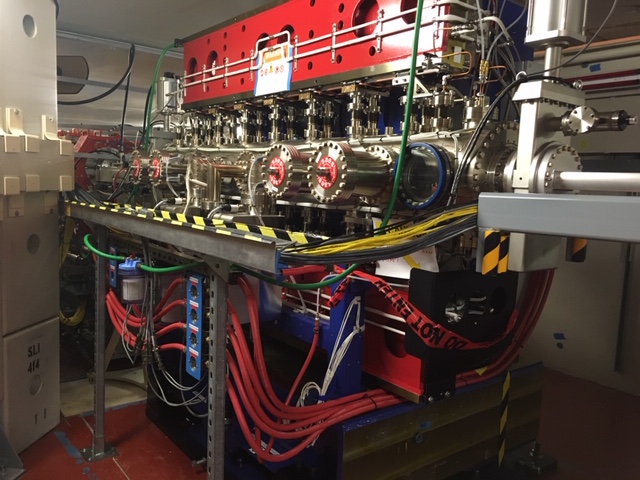

Apologies for the lack of posting to the Sector 2 blog recently. We thought we would have our final review in July, but several issues were found, and these had to be resolved before the final review. It seems that some rules for building beamlines have changed since Gemini construction began, or at least, rules are now being interpreted in a different way. The issues were: 1) inadequate thickness of radiation shielding in several places along the beamline, 2) the final hutch shutter was the wrong type, and 3) the hard-stops on the undulator had to be moved. We have to give credit to the engineering group who did a great job in fixing all these issues quickly, with new shielding designed, fabricated, and installed faster than ever before. Now, we are finally (again) ready for the final review, which has been set for Feb 12. Below is a picture of the leda, where the photons start (top) and the new hutch shutter (bottom), where the photons stop.

May 1, 2019

The robot is installed! This is a robot from NatX-Ray, and the experts from that company are here onsite for 3 weeks to commission the robot in the hutch. In the middle picture below are Quentin and Melodie, our fearless robot installers. In the picture on the right is Troy, our fearless LN expert turning on the LN to the Gemini hutch for the first time.

April 29, 2019

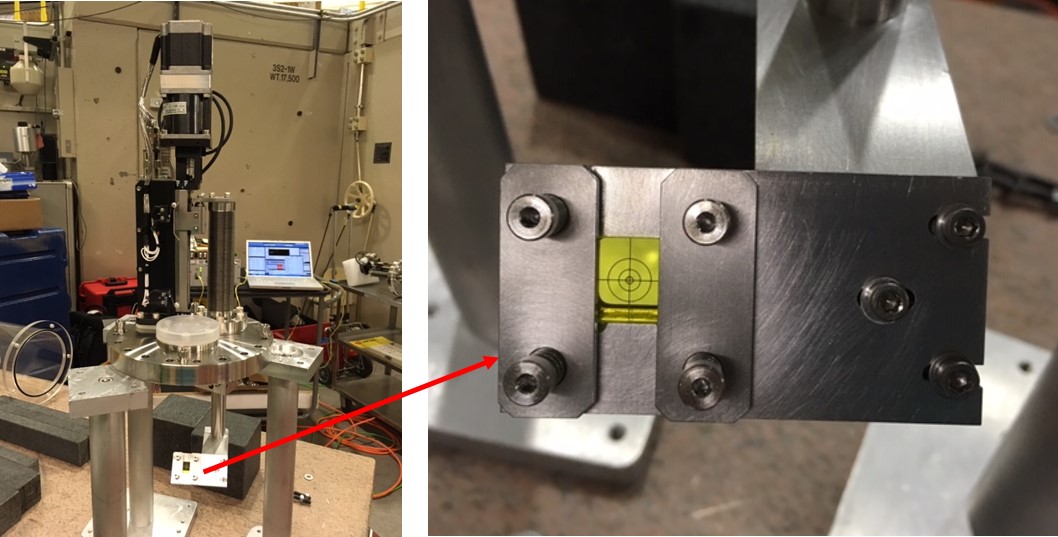

Here is one of the fluorescent diagnostic screens on the bench in the Survey and Alignment group for fiducialization. The assembly consists of a fluorescent screen on a motor so that the screen can be driven in and out of the beam. Close-up shows the screen itself with the crosshairs. We are surveying these in to within ~50 microns of where the beam will theoretically be once we have light.

April 3, 2019

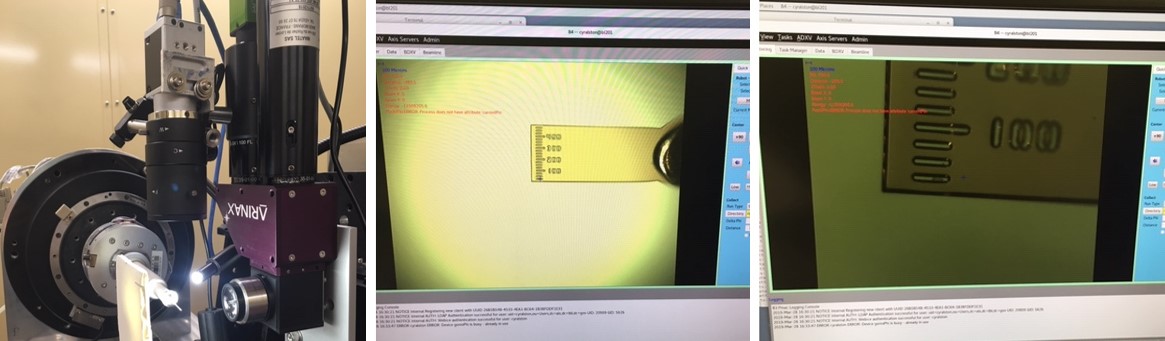

Viewing camera and goniometer installed! Though we are holding out for a fancier goniometer in the future, pending funding, this will get us through commissioning. The automounter has also passed its Factory Acceptance Tests and is due to be shipped the last week of April. And the basic beamline software has been installed. Here are images of the medium and high mag images of a pin on the goniometer, as seen through the software. The scale is 100 microns.

Jan 17, 2019

The through-pipe (ring to beamline) is in, and the first of the lead has been installed.

Jan 8, 2019

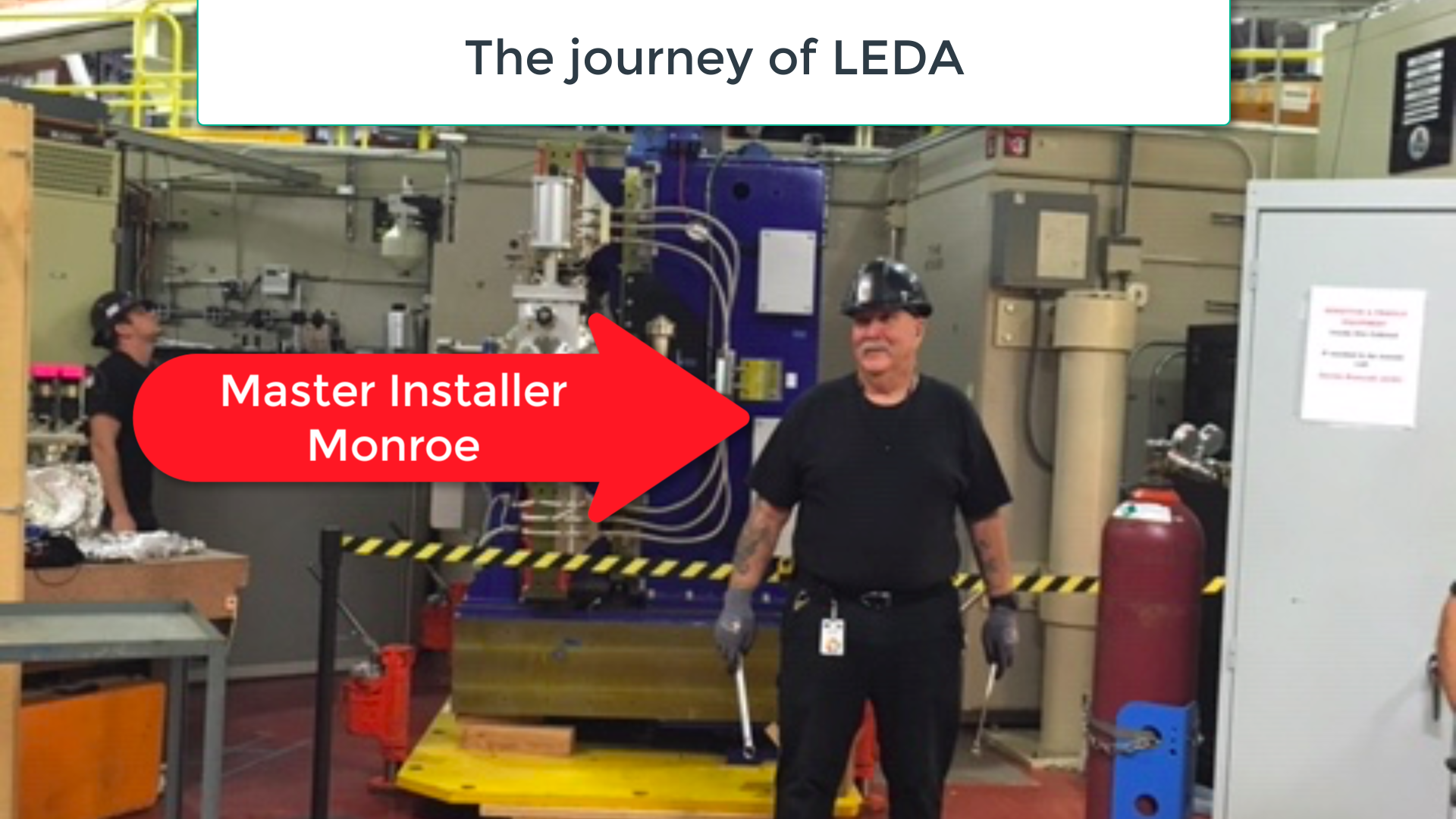

LEDA the Undulator is in! It was quite an exciting day at the ALS as LEDA was hoisted high in the air and made a giant circuit of the ALS ring before being lowered into sector 2. We took lots of video and will post those soon. Below is a “before” and “after” inside the ring with the roof block removed:

Jan 7, 2019

The front end aperture stand has been installed. Yes, the Thomas-the-Train face will be taken off before we have X-rays go through it.

Dec 21, 2018

Some slightly disappointing news: the robot has been delayed, and will not arrive until March. But, the Factory Acceptance Test is planned onsite at the Grenoble location Feb 18-20, at least. And NatXRay sent a picture of the robot so far.

Dec 17, 2018

The second (and final) ARC meeting was held today. (ARC = Accelerator Review Committee). This review described how all the action items from the first review were addressed. Bottom line: we are still “go” for installation of the undulator in January!

Dec 13, 2018

LEDA has been baked. This is a good thing. Every vessel going into the high vacuum environment of the ALS rings needs to be baked so that it will not degrade the ALS ring vacuum. Before baking, the undulator vessel was in the 10-7 Torr range. After baking, the vacuum was in the 10-10 Torr range. Success!

Nov 13, 2018

The first of the leaded windows went in today. In the picture is Monroe Thomas, one of the absolutely amazing people working on this project.

Oct 18, 2018

Another major milestone: we held the “ARC” review for the undulator yesterday. This is the installation readiness review which covers all components of the installation plan: vacuum, magnetics testing, control system, and all interlocks. There were several action items resulting from the review (not unexpected) but no show stoppers. So far, January installation is on track…

Oct 11, 2018

Okay, now someone is just having fun….granted the front end aperture tank does look a bit like Thomas the Train.

Oct 9, 2018

The “connective tissue” of the beamline is finally coming together. These are the miscellaneous pieces like beampipes, flanges, valves, and bellows, which make up the sections between the optical components (mirrors and monochromator) and the diagnostics (fluorescence screens and apertures).

Aug 16, 2018

A milestone day for LEDA: the control system to close the undulator gap was installed and tested. We determined:

- the emergency stops work

- the gap close/open directions are correct

- the hardstops are in place

- the changes as measured via software match the changes as measured via precise micrometers

All is looking good for the visit by Hitachi next week!

July 26, 2018

The concrete plug in the shield wall was removed, measured, and replaced this week. Now the right size and number of lead bricks are being ordered to fill in the space around the beampipe when it passes through the wall (slated for install in January) and the new “belly band” design (the large sheets of lead strapped to the wall right inside the ring) is in process.

July 17, 2018

The stands to hold the diagnostics (4-jaw slits and fluorescence screens) both upstream and downstream of the mono have been installed.

July 10, 2018

The valve VVR1 has been installed. This is an important valve, because it isolates the ring vacuum, which means we can now build out further components downstream without breaking ring vacuum.

June 25, 2018

The 4-jaw slit assemblies from ADC are nearly ready to ship. These are the beam diagnostics which go both upstream and downstream of the monochromator.

May 30, 2018

The hutch sprinklers have been plumbed in. Now let’s hope they are NEVER needed.

May 16, 2018

The selection process for the Gemini robotic sample automoutner was very difficult; we received three outstanding proposals in response to the LBNL Request for Bid process. In the end, based on previous installations, expertise, and cost, we decided for NatX-Ray, a company based in Grenoble, France. Here is their conceptual layout for the robot which will be able to reach both endstations in the Gemini hutch, as seen from the top.

May 10, 2018

The Gemini monochromator tank EMPTY vs FULL.

May 8, 2018

The Gemini monochromator install is in progress. The tank (and granite base) went out onto the experimental floor today. The install of the optic is planned for next week with the vendor onsite.

April 27, 2018

The Gemini undulator has arrived! It is now in building 15, and we will commence testing of the magnetics in the next month.

March 27, 2018

The Gemini hutch walls are up. This is the area previously occupied by the Vacuum group at the ALS. The last hutch at the ALS!

Feb 12, 2018

Preparation for installation of hutch walls includes electrical work and removing of remaining vacuum group cabinets and workbenches from the area:

Jan 18, 2018

Gemini hutch walls have arrived. Some assembly required….

Dec 14, 2017

And now the careful surveying of the actual mirrors into their correct positions:

Dec 13, 2017

And now for the horizonal focusing mirror:

Dec 12, 2017

The pair of focusing mirrors is currently being installed on the floor! Before-and-after of the first mirror (the vertical focusing mirror):

Dec 1, 2017

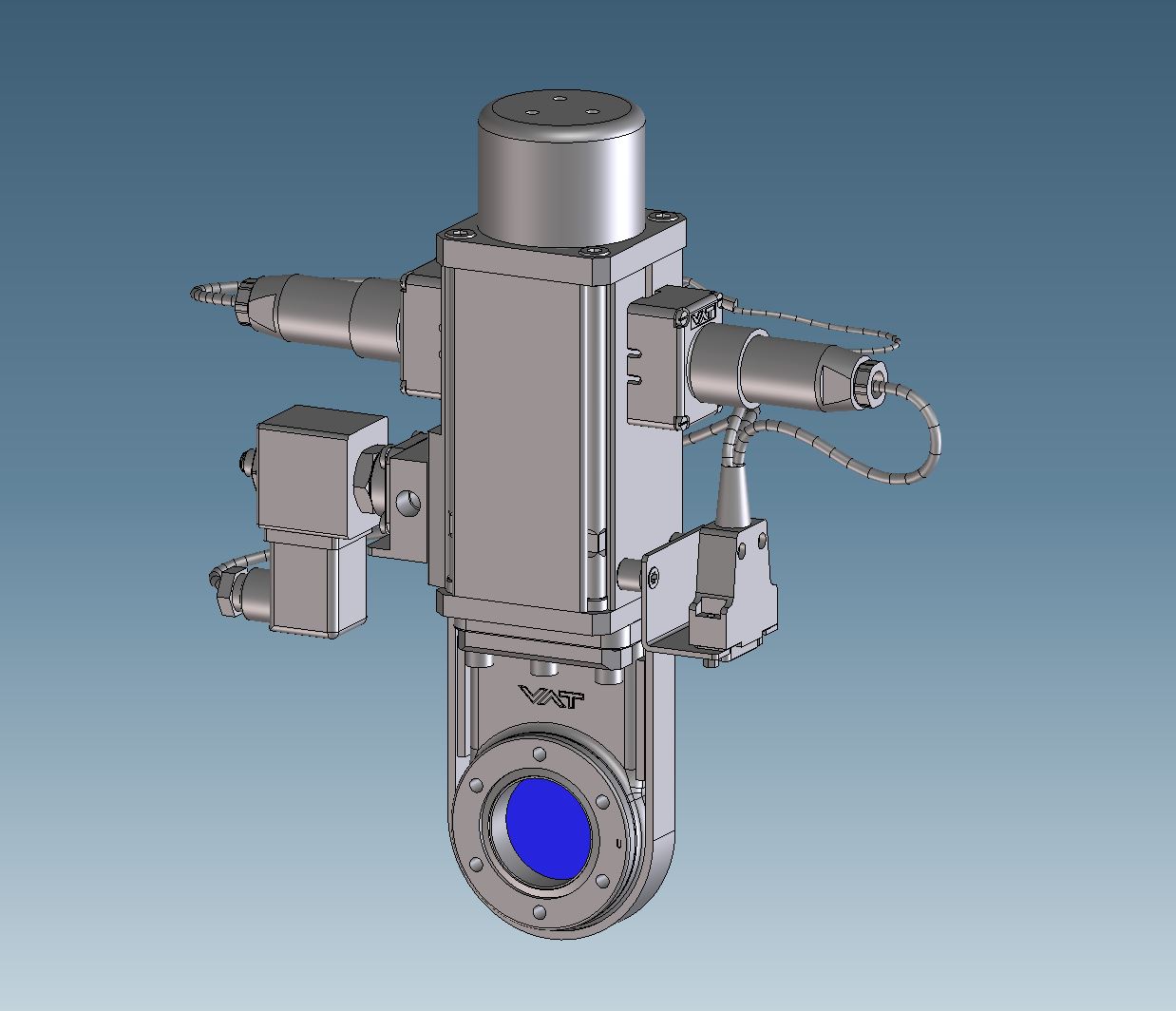

Good news and bad news for Sector 2. First, the bad news: due to a delay in construction of the specialized vacuum valves for the ALS ring, the undulator can’t go in to the ALS ring until July. We had been holding out on the hope that the valves would arrive sooner, but alas, they will not arrive until February. The ALS has scheduled a long shutdown in July to install the undulator. The good news is that all the major beamline components will be installed by then, including the mirrors, which are onsite now and due for installation next week.

August 22, 2017

The very first hardware has gone onto the experimental floor at sector 2: the first electronics racks. Maybe not super exciting, but definitely a milestone.

August 3, 2017

July 7, 2017

July 5, 2017

June 12, 2017

April 25, 2017

April 5, 2017

March 6, 2017

Feb 6, 2017

The PS/PSS (photon stop - personnel safety shutter) has arrived. This is the main shutter inside the ring for Gemini.

The unit was custom built by FMB-Oxford, and had to go through extensive review by safety at the ALS, since it is the first of its kind here, though Oxford has built similar units for the Diamond Light Source.

Jan 30, 2017

Dec 13, 2016

Nov 29, 2016

Oct 28, 2016

Oct 6, 2016

Namely, we have planned:

Install of the first aperture (AP001) inside the shield wall

Install anchors, stand, and first valve (VVR001) inside the shield wall

Install IG1 Top-Off shielding aperture inside the shield wall

Install LCW (house water system) front end manifolds, inside the shield wall

Install 2X LN2 drops (1X for the hutch, 1X for the mono) outside the shield wall

Sept 8, 2016

July 28, 2016

May 21, 2016

April 20, 2016

Feb 20, 2016

January 29, 2016

January 12, 2016

January 6, 2016

September 18, 2015

We are very fortunate to have an outstanding Scientific Advisory Board for the Gemini beamline. The board members are: Bob Fischetti (APS), Dan Harrington (SSRL), Gwyndaf Evans (Diamond Light Source) and Julian Adams (NSLS-II). All of the committee members have extensive experience in building microfocus beamlines, and the discussion during the first SAB meeting, in which we focused on the beamline optical layout and the undulator source, was extremely productive.